Did you know that about 70% of plumbing problems come from connections that aren’t quite right? That’s a big reason why measuring plumbing connector threads is super important! If you get the size wrong, it’s like trying to fit a square peg in a round hole. You end up with leaks, floods, and all sorts of messes. So, let’s jump into how to measure those tricky threads.

Back in the day, people didn’t pay much attention to size. They’d just slap on whatever fittings they had and hope for the best. As plumbing became more complicated, folks soon learned that each connection needed to match perfectly. By the 20th century, measurement tools and standards were created to help guide everyone in choosing the right sizes. Nowadays, with all the DIY projects, knowing how to measure is a must for both pros and weekend warriors alike!

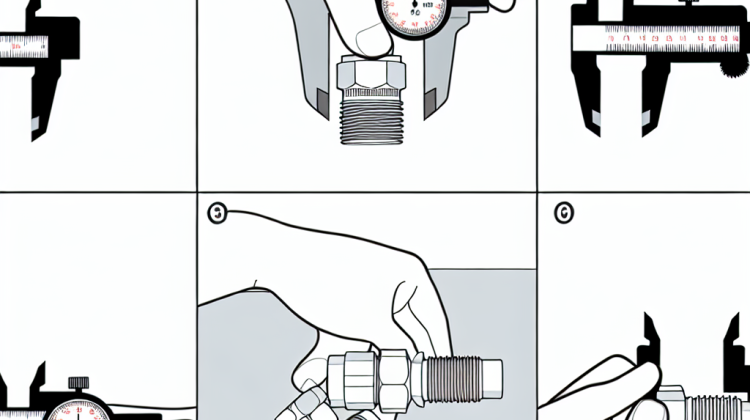

So, what’s the first step? A handy tape measure or caliper is your best friend here! Simply take the tape and wrap it around the thread. You might hear some refer to this as the “outer diameter” technique. But hold on! You also need to note the distance between the threads. It’s like counting how many grooves are on a record; knowing this can help you ensure it fits right. A good rule of thumb is to look for at least five threads, as measuring only one or two doesn’t give you the whole picture.

Here’s a fun fact—different types of plumbing connectors often have different thread styles, and the most common ones are called NPT (National Pipe Tapered) threads. They have a special design that allows them to tighten as you screw them together. That makes them great for sealing out liquids. However, they’re not all the same! Misjudging the size can lead to leaky faucets or even worse, water damage in your home.

You might wonder why this all matters. Well, statistics show that a tiny, tiny leak can waste over 10,000 gallons of water a year—that’s like filling a swimming pool! Make sure to really focus when you measure. Even a little mistake can lead to big headaches later. If you’re ever in doubt, don’t hesitate to bring your measurements to a hardware store. The folks there can help you find exactly what you need to avoid any plumbing disasters.

Before you take off with those numbers, remember that there are standard sizes for pipes and fittings, like ½ inch, ¾ inch, and so on. You can find charts online that show how to convert your measurements to these standard sizes. That way, you’ll know exactly what you need and won’t end up with a pile of parts that aren’t quite right!

Next time you think about plumbing projects, don’t forget to measure those threads right! You’ll not only save yourself a lot of effort, but your future self will definitely thank you when those pipes stay snug and dry.

How to Measure Size of Plumbing Connector Threads

Measuring the size of plumbing connector threads can feel a bit tricky, but don’t sweat it! With the right tools and a little know-how, you’re good to go. First things first, let’s talk about what you’ll need.

Gathering Your Tools

Grab a measuring tool like a caliper or a ruler. A caliper is best for this task, as it can give you more precise measurements. You might also want a thread pitch gauge. That’s a fancy tool that helps you figure out how finely the threads are spaced. Got everything? Great! Now, onto measuring.

Measuring the Diameter

Take your caliper and carefully measure the diameter of the threads. To do this, place the caliper’s jaws around the outer part of the thread. Make sure you’re holding it tight but not too tight! You want to get an accurate reading but not damage anything.

Note the measurement. Most plumbing connectors are measured in either inches or millimeters. If you’re in the US, you’ll usually see inches. But if you’re dealing with international parts, millimeters might be your best bet. Just keep an eye out for which one you need!

Checking the Thread Pitch

Next up, let’s find out the thread pitch. Here’s where that thread pitch gauge comes in handy! Take the gauge and place it against the threads of your connector. You want to find the one that fits neatly into the grooves. When you find the right gauge, it tells you how far apart the threads are from each other. This is super important because it helps you make sure everything fits perfectly!

Identifying the Type of Threads

When measuring, you should also figure out what type of threads you’ve got. There are two main types: NPT (National Pipe Tapered) and straight threads. NPT threads are tapered, meaning they get smaller as they go further down, while straight threads are the same size all the way. This affects how they seal and connect.

Look closely at your measurements and compare them to known sizes. You can find these measurements in plumbing guides or even online. Connecting the dots here will help you understand exactly what type you’re dealing with!

Checking for Compatibility

After you’ve got your measurements down, it’s a good idea to double-check them against any new parts you want to connect. Look for matching sizes and thread pitches to make sure everything fits. If you mix up sizes, things might leak, and none of us want water everywhere! Just picture that messy situation!

Final Tips

Besides using the right tools, remember to take your time. Measuring can be a bit nerve-wracking, but it doesn’t have to be. Using the right technique will lead to smoother connections and fewer headaches later on. And here’s a fun nugget of info: about 20% of plumbing issues stem from mismatched sizes in connectors. So, getting your measurements right? Totally worth it!

How to Measure Size of Plumbing Connector Threads FAQ

1. What tools do I need to measure plumbing connector threads?

You’ll need a ruler or a tape measure, and sometimes a thread pitch gauge. The gauge helps you find the spacing between threads!

2. How do I find the diameter of threaded connectors?

To find the diameter, measure from one edge of the thread to the opposite edge right in the middle. Make sure to measure in inches or millimeters!

3. What’s the difference between NPT and BSP threads?

NPT stands for National Pipe Thread, and BSP stands for British Standard Pipe. They have different angles and sizes, so they usually don’t fit together.

4. Can I use a regular ruler to measure threads?

Yes, you can! Just make sure to measure where the threads are thickest. If you have a thread pitch gauge, use that for better accuracy.

5. Why are there different sizes of threads?

There are different sizes because pipes and fittings come in various shapes and jobs. Larger pipes need bigger threads, while smaller pipes need smaller threads!

6. How do I tell if my threads are damaged?

Check for any cracks or irregular shapes. If they look worn down or uneven, it might be time to replace them!

7. Is it important to get the right size connectors?

Absolutely! Using the wrong size can cause leaks or even break your plumbing. It’s like trying to fit a square peg in a round hole!

8. Can I use a connector that’s slightly bigger?

It’s not a good idea. A bigger connector might not seal well, leading to leaks. Stick to the right size for safety!

9. Should I measure before I buy new connectors?

Yes, yes, a thousand times yes! Always measure first to make sure you’re getting the right fit. Better safe than sorry!

10. Where can I find information about specific thread sizes?

You can check manufacturer guides or search online for plumbing standards. They usually have charts that tell you all about thread sizes!

Measuring Plumbing Connector Threads

To measure the size of plumbing connector threads, you’re gonna wanna start by grabbing a ruler or a caliper. First things first, make sure to measure the outer diameter of the threads. This is super important because it helps you figure out the size of the connector. Don’t forget to measure in inches or millimeters, depending on what you’re comfortable with. You might also want to count how many threads are in one inch, which is called “threads per inch” or TPI. This tells you how tightly the threads are wound. If you see a bigger number, that means the threads are closer together.

Now, keep an eye out for the thread type, too. There are different kinds like NPT, which stands for National Pipe Thread, and they have specific shapes. Using the right type is key because not all threads fit each other. If you’re confused about what you have, don’t hesitate to compare it with a chart online or at a hardware store. Remember, measuring accurately makes a big difference when you’re connecting pipes! So, with a bit of patience and the right tools, you’ll be measuring those pesky threads like a pro in no time!