Did you know that you can create your very own plumbing test pump using PVC pipes? That’s right! This handy little device can help check for leaks in your plumbing system. It’s pretty amazing how something so simple can play such a big role in home repairs. In fact, a lot of folks don’t realize how important it is to test pipes before digging big holes or bringing in expensive professionals.

The history of using PVC for plumbing goes way back. PVC stands for polyvinyl chloride, a type of plastic that was first created in the 19th century. It wasn’t until the 1950s that it became popular for plumbing. Homeowners loved it because it was lightweight, easy to work with, and didn’t rust like metal pipes. Now, many people turn to PVC for all sorts of plumbing projects, including our little test pump. It saves time and money while helping to avoid those pesky leaks.

Here’s the fun part! If you ever find yourself with a dripping faucet or a wet spot in your yard and you think, “Uh-oh, something’s wrong!” using a PVC test pump is a pretty straightforward solution. You can whip one up with just a few materials, like some PVC pipes, connectors, and a cap. It’s like when you finally open that jar of peanut butter you’ve been eyeing forever—you can whip up something tasty and useful in no time.

First off, you’ll want to gather your supplies. Grab about 10 feet of PVC pipe, three connectors, and a cap. That’s all you need to get started! Most people can find these items at a local hardware store without much fuss. The cool thing about PVC is that it’s often inexpensive. Plus, you can even repurpose old pipes lying around if you’ve got them. Doing this not only gives you a sense of accomplishment but also helps the environment. Talk about a win-win!

Once you’ve got your materials, it’s time to put it all together. Cut the PVC pipe into different lengths for easy handling—think of it like building with LEGO bricks. Connect the pieces using the connectors to form a basic square shape. You can make it any size you want, too! Just be sure it’s tall enough to hold water. When everything is fitting just right, pop on the cap to keep the water from splashing all over the place.

Now, here’s where the magic happens. Your DIY test pump is ready to use! Fill it with water and connect it to the section of plumbing you want to check. Watch for any leaks or weird sounds. If everything’s tightly sealed, you’re good to go! Maybe even grab a snack while you wait to see if your pump does its job. If it doesn’t hold the water, that means you might have a leak somewhere, and that’s where your journey of fixing things begins!

Building a plumbing test pump from PVC isn’t just a fun project; it’s also a great learning experience. Plus, it empowers you to take care of your home without needing to break the bank. In today’s world, knowing how to tackle home repairs can turn you into a mini superhero! So roll up your sleeves, get creative, and dive into the world of plumbing with your very own test pump. You might just surprise yourself with what you can do!

How to Make a Plumbing Test Pump Out of PVC

If you’ve ever had a leaky pipe, you know how important it is to test your plumbing system. One handy tool for checking leaks is a plumbing test pump. A simple one can be made using PVC pipes and fittings. Let’s get right into it!

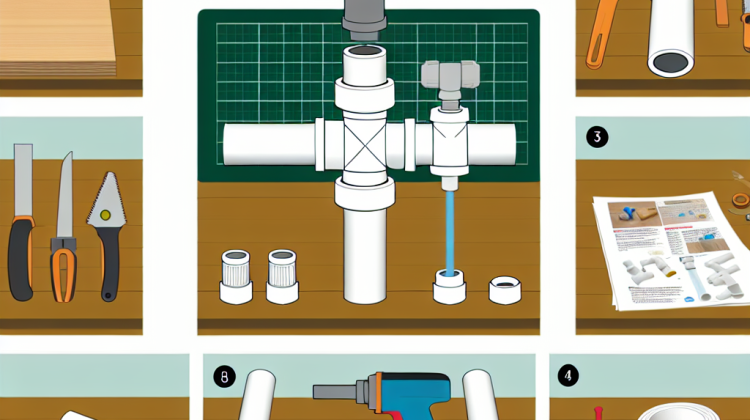

Gather Your Supplies

First off, you’ll need some materials. Here’s a quick list:

- PVC pipe (around 2 or 3 inches in diameter)

- PVC fittings (like elbows and tees)

- PVC glue

- End caps

- A valve (like a ball valve)

- Water source (a bucket will do)

Cutting the PVC Pipes

Next, grab your handy-dandy measuring tape and cut the PVC pipes to the lengths you need. Usually, you’ll want a longer piece for the main body and shorter pieces for the handles. Make sure you cut them cleanly. After all, nobody likes a jagged edge!

Assembling the Pump

Now comes the fun part—putting it all together. Start with the main pipe. Attach an end cap at one end. Then, using your PVC glue, connect a short pipe to another end of the main pipe. It’s kinda like building a LEGO tower, but with pipes!

After that, add a valve to control the water flow. Just make sure it’s pointing in the right direction. Nobody wants a surprise spray in the face! Then, glue on more fittings, depending on your design. If you need to change direction, that’s where the elbows come in handy.

Testing the Pump

Once everything’s glued and dried, it’s time to test your creation. Grab that water source and fill your pump. You can use a bucket for this. Open the valve and see if water flows smoothly. If it does, great job! If you notice any leaks, just tighten your fittings or add a bit more glue.

Using the Plumbing Test Pump

Now that you’ve got your plumbing test pump ready, it’s time to put it to work. You can push water into your plumbing system to check for leaks. Just hook it up where needed and use the valve to control the flow. Keep an eye on your pipes and joints. If you see water escaping, it’s time to fix those leaks!

Handy Tips

Here are some quick tips to make your plumbing test pump even better:

- Make sure the glue dries completely before using it, or you might get a big mess!

- If you want a longer pump, just add more pipe!

- Always check local codes, just to be on the safe side.

Fun Fact

Did you know that around 10% of homes have leaks that waste more than 90 gallons of water a day? That’s a lot of water down the drain! So, using a plumbing test pump to find those sneaky leaks can save you big bucks on your water bill.

“`html

How to Make a Plumbing Test Pump Out of PVC FAQ

What materials do I need to make a plumbing test pump?

You’ll need some PVC pipes, connectors, a valve, and a handle. Make sure to grab some glue or tape to keep everything tight!

How do I start building the pump?

First, cut your PVC pipes to the right lengths. Then, use the connectors to put them together like a fun puzzle! Just remember to use glue on the joints so they don’t leak.

What size pipes should I use?

It’s best to use 1-inch or 2-inch PVC pipes. They’re the most common sizes and work well for small plumbing jobs.

Can I use old PVC pipes for this project?

Sure, as long as they’re not cracked or damaged. Clean them up, and they should do just fine for your test pump!

Do I need special tools to build the pump?

Not really! A saw to cut the pipes, some sandpaper to smooth the edges, and a wrench for tightening will do the trick!

How do I make it work?

Once you’ve built your pump, you can pump water by moving the handle up and down. Just make sure to fill it with water first, or it won’t work!

Can I use this pump for other things?

Absolutely! You can use it to test for leaks or even drain small pools or tanks. It’s handy for all sorts of stuff!

What if it starts leaking?

If you see any leaks, check your connections. You might need to add more glue or tape to seal it up tight!

Is it safe to use a PVC test pump?

Yes, it’s safe as long as you use it correctly. Just don’t use it for bad chemicals or hot water, and you’ll be good!

How long will it last?

If you take care of it and don’t use it too roughly, your PVC pump can last for years. But like anything, it might need some repairs now and then.

“`

Conclusion

So, making a plumbing test pump out of PVC is pretty straightforward. First, start with some PVC pipes and fittings. You’ll need a few connectors and a ball valve to make it work right. Cut your pipes to the lengths you want and glue the pieces together using PVC cement. Don’t forget to let it dry completely! Once that’s done, attach the valve at the bottom. This is where you’ll fill the pump with water.

Next, when you want to test your plumbing, just close the valve, fill up the pump, and open it when you’re ready to check for leaks. It’s really that simple! But always be careful and double-check everything to make sure it all fits snugly. In the end, you’ve created a handy tool that can save you time and money. Now you’re all set to tackle those plumbing issues like a pro!