Did you know that copper pipes have been used for plumbing for over 2,000 years? Yup, ancient Egyptians and Romans used them for their water systems! It’s pretty amazing how something so old is still important today. Copper is a strong metal that doesn’t rust and can handle hot water like a champ. That’s why folks still choose copper for plumbing connections now. If you’re thinking about fixing your own plumbing, learning how to make these connections is super handy.

Back in the day, plumbers had to get creative. They didn’t have fancy tools or gadgets like we do now. Instead, they made connections using lead, which isn’t safe for drinking water. Thankfully, we learned that copper is way better! Now, with copper plumbing, you get clean water flowing through your home without worrying. Today, most homes use copper for their pipes, making it the gold standard for plumbing.

So, how do you actually connect those shiny copper pipes? First things first, you’ll need some tools. It’s like your plumbing toolbox becomes a magic wand! You’ll want a pipe cutter, a torch, solder, and flux. The pipe cutter helps to make nice, clean cuts, so your connection stays strong. No one wants their pipes leaking all over the place!

Once you’ve got your pipes cut to the right size, cleaning the ends is next on the list. Give them a good scrub with some emery cloth. Think of it like giving your pipes a little spa treatment before their big day! Cleaning the ends helps the solder stick better, and you want a strong connection that lasts. After that, you’ll dab some flux on the cleaned edges. This stuff is like glue but for metal! It helps the solder flow and makes a solid bond.

Next up, it’s time to heat things up! Don’t just jump in there with the torch too fast. Aim it at the joint, and wait for it to get nice and hot. You’ll know it’s ready when you see a little shimmer. Once it’s hot enough, touch the solder to the joint. It should melt and work its way into the gap. It’s like magic, watching it flow! And remember, keep moving the torch around to heat evenly—like dancing with your tools!

After you’ve got a good connection, don’t rush it! Let it cool down naturally. This step is super important because cooling too fast can mess up the joint. Imagine trying to eat ice cream too fast—it could give you a headache! So, be patient. Once it’s cool, wipe off any extra flux, and boom, you’re done! Your copper plumbing connection is good to go and ready to carry water.

How to Make Copper Plumbing Connections

Making copper plumbing connections can seem tricky at first, but once you get the hang of it, you’ll feel like a pro! Copper pipes are great because they last a really long time and are tough against leaks. Let’s dive in and see how to do this step by step.

Gathering Your Supplies

Before jumping in, you’ll need some tools and materials. Here’s what you’re gonna need:

- Copper pipes

- Copper fittings

- Solder

- Flux

- Pipe cutter

- Soldering torch

- Wire brush

- Safety goggles

- Gloves

It’s super important to have all your supplies ready. You don’t want to rush off in the middle of a project to find something you forgot!

Preparing the Pipes

Now that you’ve got everything, let’s start prepping your copper pipes. First things first, put on your safety goggles and gloves. Safety first, right? Use the pipe cutter to cut your copper pipes to the desired length. Remember, it’s key to make straight cuts for a good connection.

Once your pipes are cut, use a wire brush to clean both the ends of the pipes and the insides of the fittings. This removes any dirt or oxidation. If you skip this step, it could mess up your connection, and we don’t want that!

Applying Flux

Time to apply some flux! Flux is a special paste that helps the solder stick and prevents oxidation. Just dab a little on the cleaned ends of the pipes and inside the fittings. You don’t need a ton, just a thin layer.

Joining the Pipes

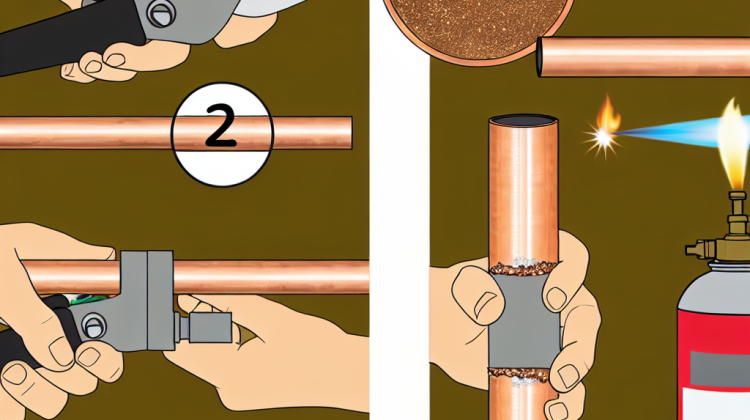

Next up, slide the copper fitting onto the pipe. Make sure the pipe goes in all the way; it should fit snugly. If it doesn’t, you might need to make some adjustments. Now, if you see gaps, it’s a no-go. Gaps can cause leaks later on!

Soldering the Connection

Getting to the fun part, soldering! Light up your torch and heat the joint where the pipe and fitting meet. Be careful not to burn the flux away, but get it nice and hot. When you start seeing the flux sparkle, that’s your cue to melt the solder. Touch the solder to the hot joint—it should melt and flow into the gap. Keep heating until you see the solder go all around the joint.

Once you’ve got a nice flow, remove the torch and let it cool. Don’t touch it just yet; it’s super hot! Give it a few minutes to set.

Checking Your Work

After it cools down, check that your joint looks good. It should have a shiny appearance. If there are any gaps or holes that didn’t fill with solder, you might need to go back and fix it. And remember, always double-check for leaks by turning the water back on and watching for drips.

Fun Fact

Did you know that using copper pipe can make your plumbing last for around 50 years? That’s a long time to avoid leaks!

“`html

How to Make Copper Plumbing Connections FAQ

1. What tools do I need to make copper plumbing connections?

To make copper plumbing connections, you’ll need a few basic tools: a pipe cutter, a propane torch, flux, solder, and a wire brush. Don’t worry, they’re not hard to find!

2. How do I cut copper pipes?

Cutting copper pipes is pretty easy! Just use the pipe cutter, clamp it onto the pipe, and turn it around a few times until it breaks. It’s like a giant cookie cutter but for pipes!

3. Do I need to clean the pipes before connecting them?

Absolutely! Cleaning is super important. Use a wire brush to scrub the ends of the pipes so the solder sticks better. Think of it as making sure the glue sticks to the paper!

4. What’s flux, and why do I need it?

Flux is like magic toothpaste for pipes! It helps the solder flow and stick to the pipes. Just put a bit on the ends before you join them. It makes the connection strong!

5. How do I heat the pipes for soldering?

Using a propane torch, heat the joint where the pipes meet. Move the flame around so it heats evenly. You want it hot, but not so hot that it burns. It’s all about finding that sweet spot!

6. How do I know when to add solder?

When the copper looks shiny and hot, it’s time to add the solder! Just touch the solder to the joint—it’ll melt and flow right into the space. It’s like pouring chocolate into a melted mold!

7. Can I make connections without a torch?

If you can’t use a torch, you can try crimp fittings. These use a special clamp instead of heat, making them easier to work with. Sometimes you gotta roll with what you’ve got!

8. What’s the best way to avoid leaks?

To avoid leaks, make sure your pipes are clean, use enough flux, and heat them properly. Then let the connection cool down before using it. Patience pays off!

9. Is it safe to work with propane torches?

Definitely! Just be careful and use common sense. Keep the area well-ventilated, and have a fire extinguisher handy. Safety first, folks!

10. What if I make a mistake?

No worries! If something goes wrong, you can always cut the pipe and start over. It happens to everyone, so don’t sweat it! Just take a deep breath and try again!

“`

Wrapping It Up: Copper Plumbing Connections

To make copper plumbing connections, start by cutting your copper pipes to the right length. Use a pipe cutter for a clean cut, and remember to deburr the edges so there are no sharp bits sticking out. After that, fit the pipes together with a fitting, like a coupling or elbow, and be sure to clean both the pipes and the fittings using a wire brush. This step’s super important! Next, you’ll want to apply some flux—it’s like a magic glue that helps the solder stick. Put the fitting back on, and heat it with a torch until the solder melts. Don’t forget to let it cool down before you go touching it!

Now, once your connections are made, check for leaks. You don’t wanna find out the hard way that something’s not quite right! If there are any drips, you’ll have to go back and fix them. And there you have it! By following these simple steps—cutting, cleaning, applying flux, soldering, and checking—you can create strong and safe copper plumbing connections. It might seem tricky at first, but with a little practice, you’ll be a pro in no time! Just remember, safety first! Always wear goggles and work in a well-ventilated area when using that torch. You’ve got this!