Did you know that NPT stands for National Pipe Thread? It’s a standard you’ll see in plumbing everywhere! NPT compression fittings are important for making strong connections in pipes that carry everything from water to gas. They’re popular because they create tight seals that help prevent leaks, which is a big deal when you’re dealing with plumbing.

The way NPT connections work goes way back. In the early days, people used all sorts of methods to join pipes, but they often had problems with leaks and breaks. Over time, engineers figured out that using a tapered thread gave a better grip and made connections more secure. That’s how NPT came to be! Nowadays, nearly everyone doing plumbing work—whether it’s in homes or big buildings—relies on these connections. They’re like the unsung heroes of plumbing!

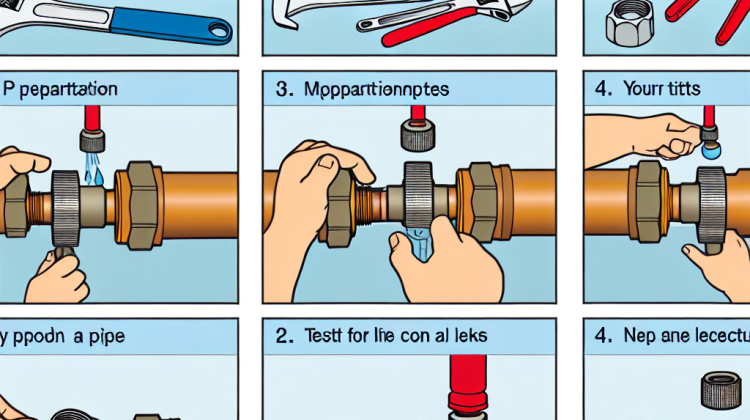

Now, let’s talk about how to actually make an NPT compression plumbing connection. First things first, gather your tools! You’ll need an adjustable wrench, some plumber’s tape, and of course, your NPT fittings. To start the process, make sure the pipe you’re working with is clean and dry. It’s kinda like cleaning your room before you invite friends over—nobody wants to deal with a mess!

Once you’re ready, wrap the threads of your pipe with plumber’s tape. This tape helps to seal everything up so there are no sneaky leaks. Make sure to wrap it neatly around the threads a couple of times. Then, take your fitting and screw it onto the pipe. Remember, it should go on easily at first. If you feel resistance, back it off—don’t force it!

Now, here’s the fun part: tighten it up! Grab your adjustable wrench and turn the fitting until it feels snug. But don’t go overboard! You don’t want to risk damaging the threads. A little trick is to tighten it just until you feel it give a tiny bit more—like the ‘kiss’ of a good handshake.

After you’ve got everything snugged up, it’s time to check your work. Turn on the water or gas slowly and watch for any leaks. If you see any drops, you might need to tighten it a bit more or reapply the tape. Like they say, “A stitch in time saves nine!” You’ll be glad you checked.

Doing an NPT compression plumbing connection might seem a bit tricky at first, but with a little practice, you’ll get the hang of it. And just like that favorite recipe you keep coming back to, you’ll feel more confident every time you do it. So, gear up and get ready to tackle that plumbing project!

How to Make an NPT Compression Plumbing Connection

Making an NPT compression plumbing connection might sound tricky, but it’s really not too bad once you get the hang of it. Let’s jump right into it!

Gather Your Tools and Materials

First things first, you need to grab a few things:

- NPT (National Pipe Thread) fittings

- Compression nuts and rings

- Pipe wrench or adjustable wrench

- PTFE tape (also known as plumber’s tape)

- Cutting tool for pipes (if needed)

Prepare the Pipe

Now that you’ve got your tools, it’s time to prep the pipe. If you’ve got a pipe that’s longer than you need, grab that cutting tool and trim it down to size. Just make sure the cut’s nice and straight, so everything fits snugly later.

Thread the Fittings

Once you’ve got your pipe ready, it’s time to thread those fittings. Take the PTFE tape and wrap it around the threads of the NPT fitting. Just a few turns will do the trick! Make sure to wrap it in the same direction that you’ll be screwing it on. This helps to seal the connection and keeps any leaks from sneaking out.

Attach the Compression Nut and Ring

Next up, slide the compression nut and ring onto the pipe. The ring should slide right after the nut. Remember, it’s the ring that makes the connection tight… so don’t skip this step!

Connect Everything Together

Now comes the fun part! Take that fitting you just wrapped with tape and screw it onto the pipe. Make sure to keep turning until it feels nice and snug. This is where the wrench comes in handy. Don’t go overboard; just give it a little extra twist to ensure it’s tight without bending anything!

Tighten the Compression Nut

After securing the fitting, it’s time to tighten the compression nut. Use your wrench to turn it clockwise until it feels snug. This part is crucial because it squishes the compression ring, creating a solid seal. Check to see if there’s any movement; if there is, you might need to tighten a smidge more!

Test for Leaks

Time to put your work to the test! Turn on the water slowly and watch for leaks. If you see droplets forming, don’t panic! Just turn off the water and tighten things up a bit more. Sometimes it just needs an extra twist or two.

Did You Know?

More than 10 billion gallons of water are wasted each year because of leaks in home plumbing systems. That’s a lot of water going down the drain!

“`html

How to Make an NPT Compression Plumbing Connection FAQ

What does NPT stand for?

NPT stands for National Pipe Thread. It’s a standard used for threaded pipes in plumbing.

Why is NPT used?

NPT is used because it helps create a tight seal when connecting pipes, preventing leaks.

What tools do I need to make an NPT compression connection?

You’ll need a pipe wrench, a cutting tool, and sometimes Teflon tape for sealing.

Can I use NPT connections for gas lines?

Yes, NPT connections can be used for gas lines. Just make sure they’re installed correctly to avoid leaks!

How do I know what size NPT fitting to use?

You can measure the diameter of the pipe. NPT fittings come in various sizes, so it’s important to match the size!

What’s the difference between NPT and other types of fittings?

The main difference is in how the threads are shaped. NPT has tapered threads, while other types like NPS have non-tapered threads.

Do I need to use Teflon tape with NPT connections?

It’s a good idea! Teflon tape can help seal the threads better and prevent leaks.

How tight should I make the connection?

You should tighten it enough to create a seal, but be careful not to overtighten and damage the fitting!

What if my NPT connection leaks?

If it leaks, try tightening it a little more. If that doesn’t work, you may need to take it apart and reapply Teflon tape.

Are there any risks with NPT connections?

Yes, if they’re not installed properly, they can leak, which may lead to water damage or other problems!

“`

Conclusion

So, to wrap it all up, making an NPT compression plumbing connection isn’t as tricky as it sounds! First things first, you’ll want to gather your tools and materials, like the pipe, fittings, wrenches, and some Teflon tape to make everything snug and tight. Don’t forget to clean the threads on both ends—this helps create a smooth connection. When it’s time to connect, simply line up the male thread and female fitting, and twist them together. You’ll want to make sure it’s hand-tight first and then give it a little extra turn with a wrench. But be careful; don’t overdo it!

Just remember to check for leaks once you’re done. Turn on the water slowly and look for any drips or wet spots. If you spot a leak, just tighten a bit more. And voilà! You’ve successfully made your NPT compression plumbing connection. Simple as pie, right? With a little practice, you’ll be a pro in no time. Keep these tips handy, and you’ll have those pipes connected like a champ, ready to go!