Did you know that copper pipes have been used in plumbing for thousands of years? Yup, it’s true! The ancient Romans relied on copper for their aqueducts and real fancy baths. Fast forward to today, and copper is still a favorite material for plumbing. It’s strong, long-lasting, and it can handle hot and cold water like a champ. But do you know how to make a 1/2-inch copper compression plumbing connection? Let’s dig right in!

Making a 1/2-inch copper compression connection isn’t rocket science, but it’s super important to do it right. The whole idea is to join two copper pipes without leaving leaks behind. This type of connection uses a special fitting that grips the pipe tightly when you tighten a nut. It’s like giving a big, warm hug to the pipes! This method is more popular now because it can be done without soldering, which means you don’t need a blowtorch or fancy skills. Just good old-fashioned handiwork!

Now, let’s talk about what you’ll need before you get started. You’ll need a 1/2-inch copper pipe, a compression fitting, a wrench, some plumber’s tape, and, most importantly, a good attitude! It’s always easier to work through a project when you’re happy and ready to go. You know what they say, “A smile is the best tool in the toolbox!” Having the right tools makes your job smoother, just like butter on warm bread.

Once you’ve gathered your materials, it’s time for some simple steps. First, cut your 1/2-inch copper pipe to the length you need. Remember, you wanna make sure the edges are super clean. No rough edges allowed! Next, slide one part of your compression fitting onto the pipe. It should fit snugly. Now, grab the nut from the fitting and put it on the pipe too. It’s like putting on your favorite cap—it just fits perfectly!

Next up, twist that nut onto the fitting. This is where the magic happens! As you tighten the nut, it pulls the fitting closer to the pipe, creating a tight seal. Be careful not to go too overboard though; you don’t want to break anything. It’s like trying to open a jar—you don’t need to use all your strength! Just enough to keep it secure will do.

Before calling it a day, give your connection a little test. Turn on the water and check for leaks. If you see water trickling out, oh no! You might need to tighten the connection a bit more. If it’s running smooth as a whistle, pat yourself on the back. You’ve done a great job! Copper compression connections are a handy skill that makes plumbing fixes a breeze. So go on, roll up those sleeves and get to work!

How to Make a 1/2 Copper Compression Plumbing Connection

If you’re planning to do some plumbing work, making a 1/2 copper compression connection isn’t too tricky. It’s like piecing together a puzzle! Just follow these simple steps, and you’ll be all set in no time. Grab your tools and let’s go!

Gather Your Tools and Materials

First things first, you gotta have the right stuff. Here’s what you’ll need:

- 1/2-inch copper pipe

- Compression fitting

- Pipe cutter

- Sandpaper or a reamer

- Adjustable wrench

Measure and Cut the Copper Pipe

Now, get your copper pipe and measure it out. Make sure it’s the right length for your plumbing job. Once you’ve got your measurement:

- Take your pipe cutter and put it where you wanna cut.

- Turn the cutter around the pipe a few times until it cuts through. Easy peasy!

Prep the Pipe End

After you’ve cut the pipe, it’s super important to make it nice and smooth. You don’t want any rough edges, as they can mess things up when you connect everything. Take some sandpaper or a reamer, and:

- Lightly sand the end of the pipe.

- Make sure there’s no burrs or sharp spots.

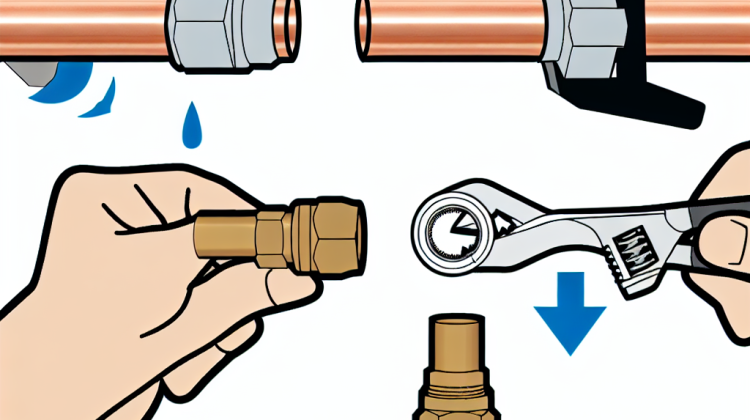

Put on the Compression Fitting

Next up, it’s time to slip on the compression fitting. It’s like putting a ring on a finger! Here’s how:

- Slide the compression nut onto the pipe first.

- Then, add the compression ring (also called a ferrule) over the pipe end.

Connect the Fitting

Now that you’ve got the fitting ready, it’s time to connect it. This part is super important, so pay attention:

- Push the pipe into the fitting as far as it can go. You want a snug fit, but not too snug!

- Hold the fitting steady while you screw on the compression nut.

- Use that adjustable wrench to tighten the nut. But don’t go overboard; it just needs to be tight enough to make a seal.

Check for Leaks

Once everything’s tightened up, it’s time for the final test. Turn on the water and check for leaks:

- Look carefully at the connection. If water drips, you might need to tighten the nut a little more.

- If it’s dry as a bone, you did a fantastic job!

Did you know that nearly 10% of homes have leaks in their plumbing systems? Keeping everything tight and leak-free can save you a lot of money!

“`html

FAQ 1: What is a copper compression plumbing connection?

A copper compression plumbing connection is a way to join copper pipes using a special fitting and a compression nut. It’s a secure way to make sure the pipes stay connected and don’t leak.

FAQ 2: Do I need special tools to make a copper compression connection?

Not really! You mainly need a pipe cutter, a wrench for tightening, and maybe some sandpaper to smooth out the ends of the pipes. Pretty simple, right?

FAQ 3: How do I prepare the pipes for a compression fitting?

Start by cutting the copper pipe straight with your pipe cutter. Then, use sandpaper to clean the end of the pipe so it’s nice and smooth. This helps make a better connection!

FAQ 4: Can I reuse a copper compression fitting?

Yes, you can, but it might not be the best idea. If the fitting’s worn or damaged, it’s better to get a new one to avoid any leaks later on.

FAQ 5: Are compression fittings better than soldering?

Well, it depends! Compression fittings are easier and quicker to use, while soldering takes more time and skill. If you’re a beginner, compression is definitely a good choice!

FAQ 6: What happens if a compression fitting leaks?

If it leaks, don’t panic! First, try tightening the compression nut a bit more. If that doesn’t work, you might need to take it apart and redo it with new parts.

FAQ 7: How tight should I make the compression fitting?

Make it snug but not overly tight! You don’t want to break anything, so use a wrench to get it snug, and check for leaks after.

FAQ 8: Can I use compression fittings with other types of piping?

Sure thing! You can use them with various piping types, like PVC or PEX. Just make sure you get the right fittings for each kind!

FAQ 9: What if I don’t have the right size fitting?

No worries! Most hardware stores have plenty of options. Just take your pipe with you, and they’ll help you find the right size.

FAQ 10: Is there a limit to how many fittings I can use?

There’s no strict limit, but the more fittings you use, the more chances there are for leaks. Try to keep things simple with as few connections as possible!

“`

Wrapping It Up: Connecting Copper Plumbing Made Easy

To connect 1/2 inch copper plumbing using a compression connection, you first need to cut your copper pipe to the right length. Make sure it’s straight and smooth, or you might end up with a leak! Next, slide a compression nut and a ring onto the pipe before you put it into the fitting. It’s a bit like putting on a shirt before buttoning it up—you can’t skip that step! Once everything’s lined up, gently tighten the compression nut with a wrench. Not too tight, though! It should feel snug but not overdone, like a hug from a friend.

Remember, always check for leaks after you’re done. Just turn on the water slowly and look for any drops—like searching for a hidden treasure! If you see any water escaping, give that nut a little more twist. Before you know it, you’ll have a solid connection that’ll keep things flowing smoothly. So, whether you’re fixing a pipe or just trying something new, making a compression connection is a handy skill to have. With a bit of practice, you’ll be a plumbing whiz in no time!